In today’s manufacturing and fabrication industries, precision, versatility, and efficiency are non-negotiable. Whether you’re cutting metal, stone, glass, or composites, finding a method that avoids heat damage, maintains tight tolerances, and handles diverse materials is critical. That’s where waterjet cutting equipment shines—and Winwin Waterjet leads the way in delivering reliable, high-performance solutions for businesses worldwide.

What Is Waterjet Cutting Equipment?

Waterjet cutting is a cold-cutting technology that uses high-pressure streams of water (often mixed with abrasive particles) to slice through materials with exceptional accuracy. Unlike laser or plasma cutting, it produces no heat-affected zones (HAZs), minimizes material waste, and works on both soft and ultra-hard substrates. Winwin Waterjet’s equipment is engineered to leverage this technology, offering customizable systems for small workshops, large factories, and specialized industries.

How Does Waterjet Cutting Equipment Work?

The science behind waterjet cutting is simple yet powerful. Winwin Waterjet’s systems follow three core steps to deliver precise cuts:

1. High-Pressure Water Generation

At the heart of every waterjet machine is a high-pressure pump. Winwin Waterjet uses industrial-grade pumps that compress water to pressures ranging from 30,000 to 60,000 PSI (pounds per square inch)—that’s over 100 times the pressure of a typical garden hose! This extreme pressure converts water into a kinetic force strong enough to cut through materials.

2. Abrasive Mixing (for Hard Materials)

For cutting hard substances like steel, titanium, granite, or ceramics, Winwin’s waterjet systems add abrasive particles (usually garnet) to the high-pressure water stream. The water accelerates the abrasive, creating a “cutting jet” that acts like a precision tool—eroding material without melting or warping it. For softer materials (e.g., foam, rubber, or paper), pure water (no abrasive) is used to avoid damage.

3. Precision Cutting with Computer Control

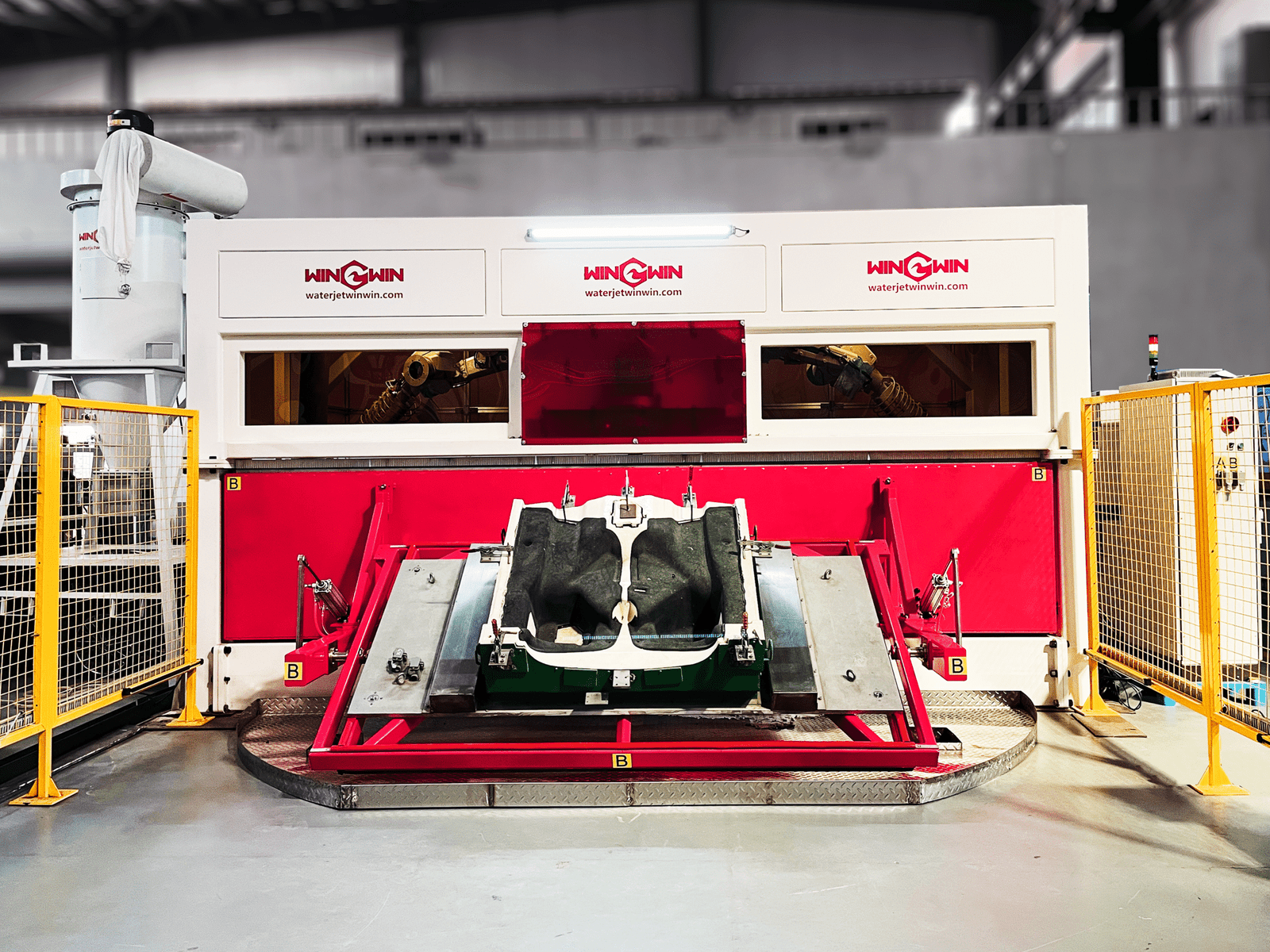

All Winwin Waterjet equipment is integrated with CNC (Computer Numerical Control) technology. Operators input design files (e.g., CAD drawings), and the machine’s robotic arm or gantry guides the cutting jet along the exact path. This ensures consistent, repeatable cuts with tolerances as tight as ±0.001 inches—ideal for intricate parts or custom designs.

Key Applications of Winwin Waterjet Cutting Equipment

Waterjet cutting’s versatility makes it indispensable across industries. Winwin Waterjet’s systems are tailored to meet the unique needs of these sectors:

1. Metal Fabrication

From stainless steel sheets for automotive parts to aluminum components for aerospace, Winwin’s waterjet equipment cuts metals without HAZs—critical for maintaining material strength. It’s also ideal for cutting thick metal plates (up to 12 inches or more) and complex shapes that would be difficult with traditional tools.

2. Stone & Tile Industry

Granite, marble, and porcelain tiles require precise cuts for countertops, flooring, and architectural details. Winwin’s waterjet systems handle these brittle materials without chipping, allowing for intricate patterns (e.g., inlays, mosaics) that enhance design flexibility.

3. Glass & Aerospace

Glass cutting demands extreme precision to avoid cracking. Winwin’s waterjet equipment cuts glass for electronics (e.g., smartphone screens) and aerospace components (e.g., cockpit windows) with minimal waste. In aerospace, it also cuts composite materials (e.g., carbon fiber) that are sensitive to heat.

4. Automotive & Electronics

In automotive, Winwin’s waterjets cut gaskets, interior panels, and engine components. In electronics, they precision-cut circuit boards, rubber gaskets, and plastic housings—ensuring components fit perfectly in tight spaces.

Why Choose Winwin Waterjet Cutting Equipment?

With so many waterjet suppliers, what sets Winwin Waterjet apart?

Customization: We design systems for your specific needs—whether you need a compact tabletop machine for small projects or a large gantry system for high-volume production.

Durability: Winwin’s pumps, nozzles, and frames are built to withstand heavy use, reducing downtime and maintenance costs.

Support: Our team provides training, technical support, and replacement parts to keep your waterjet running smoothly.

Ready to Upgrade Your Cutting Process?

Winwin Waterjet’s cutting equipment combines innovation, reliability, and versatility to help you tackle any project. Whether you’re in metal fabrication, stoneworking, or food processing, our systems deliver the precision and efficiency you need to stay competitive.

Contact us today to learn more about our waterjet solutions—or request a demo to see how Winwin Waterjet can transform your workflow.