Ceramic materials—known for their hardness, heat resistance, and aesthetic appeal—are widely used in construction, art, electronics, and industrial manufacturing. However, cutting ceramics precisely without damaging their structure has long been a challenge. Enter water jet cutting: a versatile technology that’s revolutionizing ceramic processing.

Key Applications of WaterJet Cutting in Ceramic Work

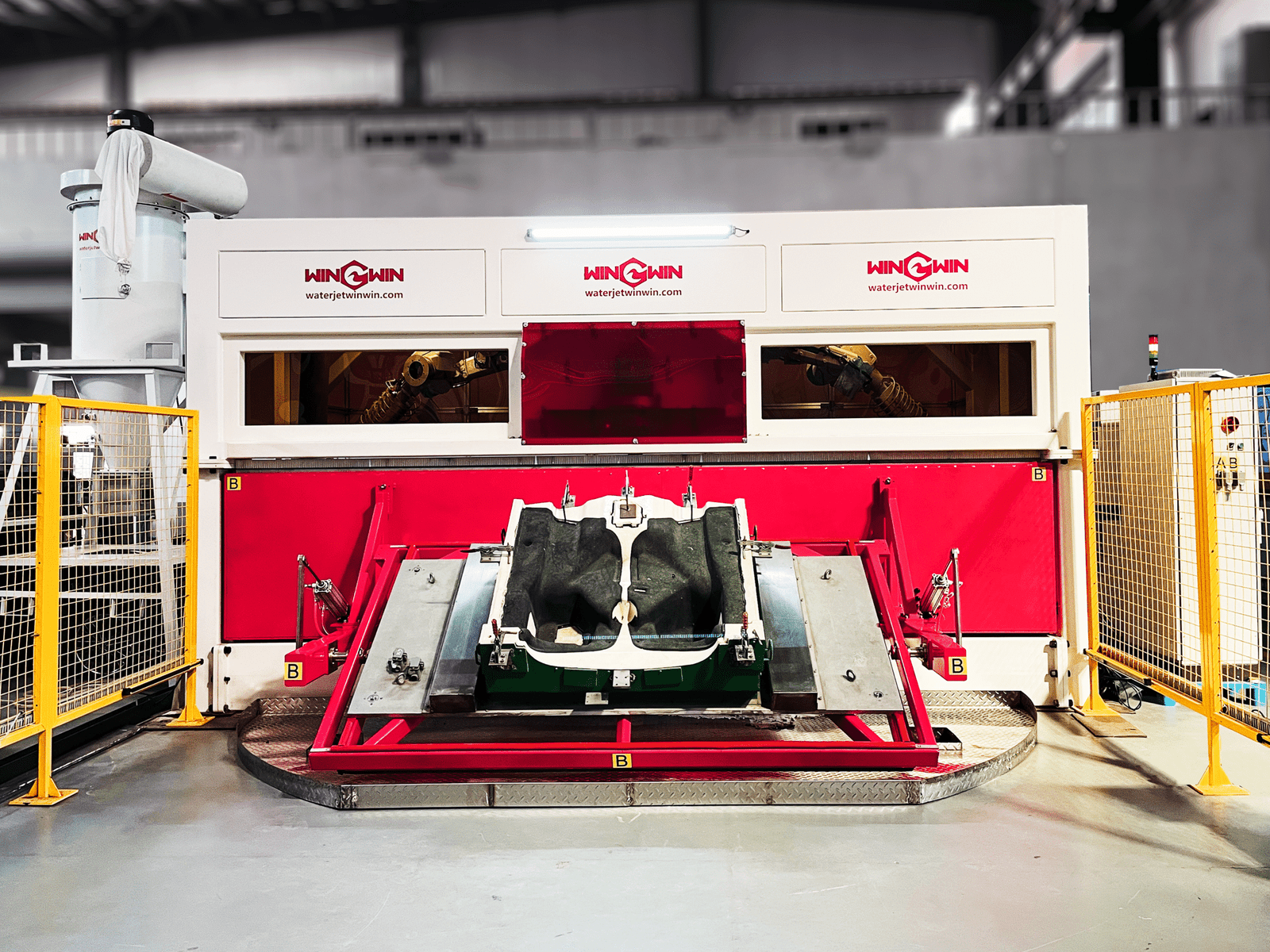

Water jet systems excel at handling ceramics of all types, from fragile decorative tiles to high-strength industrial ceramics. Common uses include:

- Custom Tile Cutting: Creating intricate shapes, curves, or mosaic patterns for flooring, walls, or backsplashes—ideal for unique architectural designs.

- Industrial Ceramic Components: Cutting precision parts (e.g., insulators, wear-resistant liners) for electronics, aerospace, and machinery, where tight tolerances are critical.

- Artistic & Decorative Pieces: Shaping ceramic sculptures, vases, or ornamental elements without chipping or cracking delicate surfaces.

Why WaterJet Cutting Stands Out for Ceramics

Compared to traditional methods like laser cutting or mechanical sawing, water jet cutting offers distinct advantages:

- No Heat Damage: Uses high-pressure water (often mixed with abrasives) to cut, avoiding thermal stress that can cause ceramics to crack or warp.

- Unmatched Precision: Achieves tight tolerances (down to ±0.1mm) even for complex geometries, ensuring clean, burr-free edges.

- Versatility Across Materials: Works on all ceramic types—porcelain, stoneware, alumina, and more—regardless of thickness or hardness.

- Eco-Friendly: Produces minimal dust and waste, with no harmful fumes, making it safer for workers and the environment.

- Reduced Material Waste: Optimizes cutting paths to maximize material usage, lowering costs for large-scale projects.

For ceramic manufacturers and artisans seeking efficiency, precision, and reliability, water jet cutting is a game-changer. It combines power with finesse, turning tough ceramic materials into polished, accurate products—whether for functional parts or artistic creations.

Ready to elevate your ceramic cutting process? Explore water jet solutions tailored to your needs.