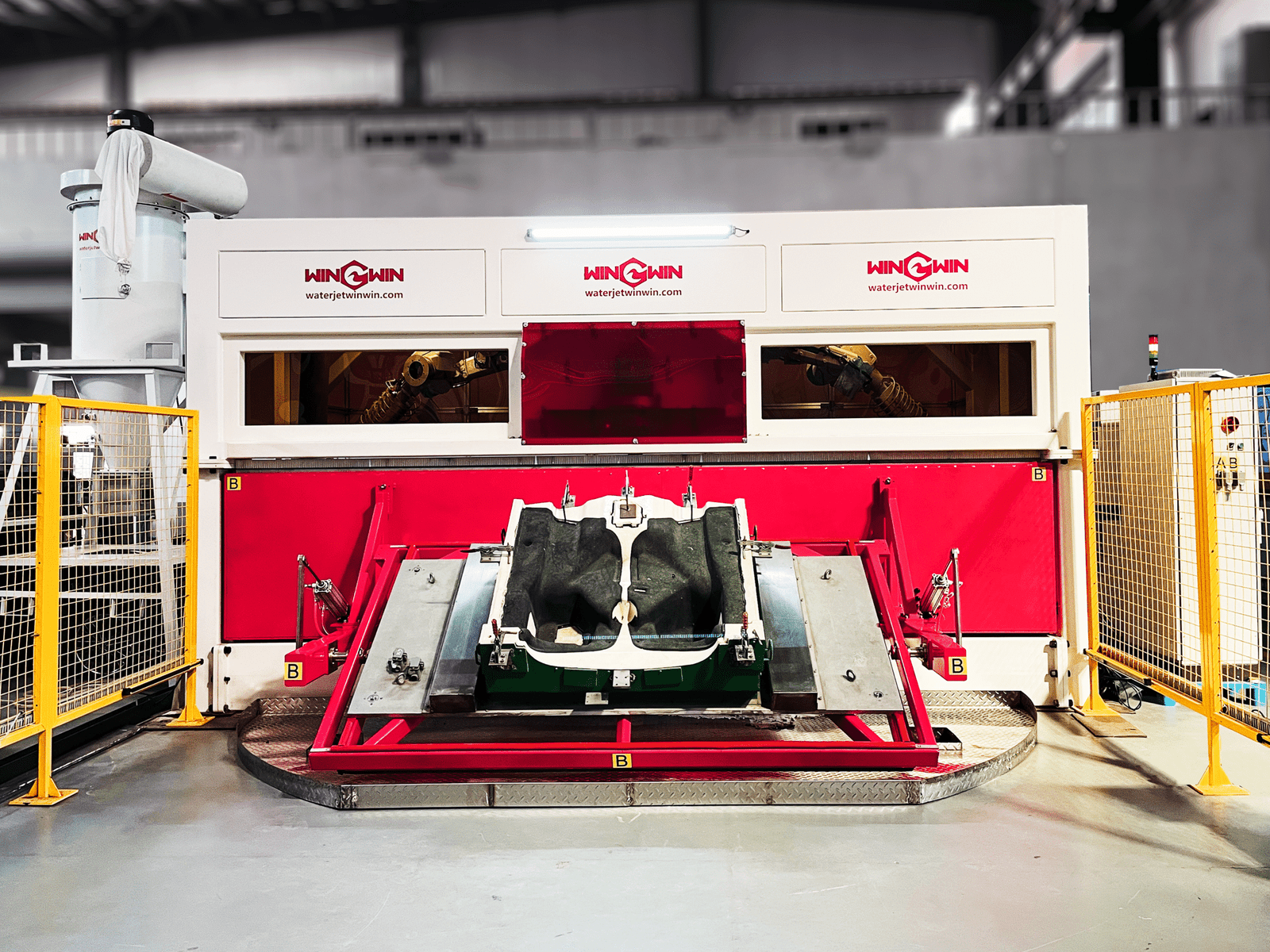

Ultra high pressure (UHP) waterjet cutting has become a game-changer for precision manufacturing, and Winwinwaterjet’s UHP cutting machines stand out for their unmatched advantages over traditional methods. From cold cutting to versatile material compatibility, these machines deliver efficiency and quality that modern industries demand.

1. Heat-Free Cutting (No HAZ)

Unlike laser, plasma, or flame cutting, Winwinwaterjet’s UHP machines use high-pressure water (with optional abrasives) for cold cutting. This eliminates heat-affected zones (HAZ), preventing material distortion, warping, or structural damage. It’s ideal for heat-sensitive materials like metals, composites, and plastics, preserving their original mechanical properties.

2. Universal Material Compatibility

Winwinwaterjet’s equipment cuts almost any material without tool changes. This includes metals (stainless steel, aluminum), stone (marble, granite), composites (carbon fiber, Kevlar), glass, acrylic, and even food. The versatility reduces production costs and streamlines workflows for businesses across industries.

3. Precision & Intricate Cutting

With advanced control systems, Winwinwaterjet’s UHP machines achieve exceptional precision (up to ±0.1mm). They handle complex shapes, tight curves, and tiny holes that traditional tools can’t match. This makes them perfect for custom parts, decorative designs, and high-precision industrial components.

4. Eco-Friendly & Safe Operation

The process uses water (and non-toxic abrasives like garnet) with no toxic fumes, dust, or chemical waste. It’s a sustainable alternative to methods that produce harmful emissions. The safe, low-heat operation also minimizes workplace hazards, complying with global safety and environmental standards.

Winwinwaterjet’s UHP waterjet cutting machines combine these core advantages to help businesses boost productivity, reduce waste, and meet strict quality requirements. Whether you’re in metal fabrication, stone processing, or composite manufacturing, their solutions offer a competitive edge.