As a leader in the high-end automotive industry, BMW has always adhered to the pursuit of exquisite craftsmanship and high-quality products in automotive interior production. Win-Win, as a professional waterjet supplier, has established an in-depth cooperative relationship with BMW’s core interior suppliers, and its robotic waterjet cutting equipment has become an important support for BMW’s high-standard interior manufacturing. The specific connection is mainly embodied in the following aspects:

1. Win-Win Waterjet Equipment: Core Support for BMW Interior Manufacturing

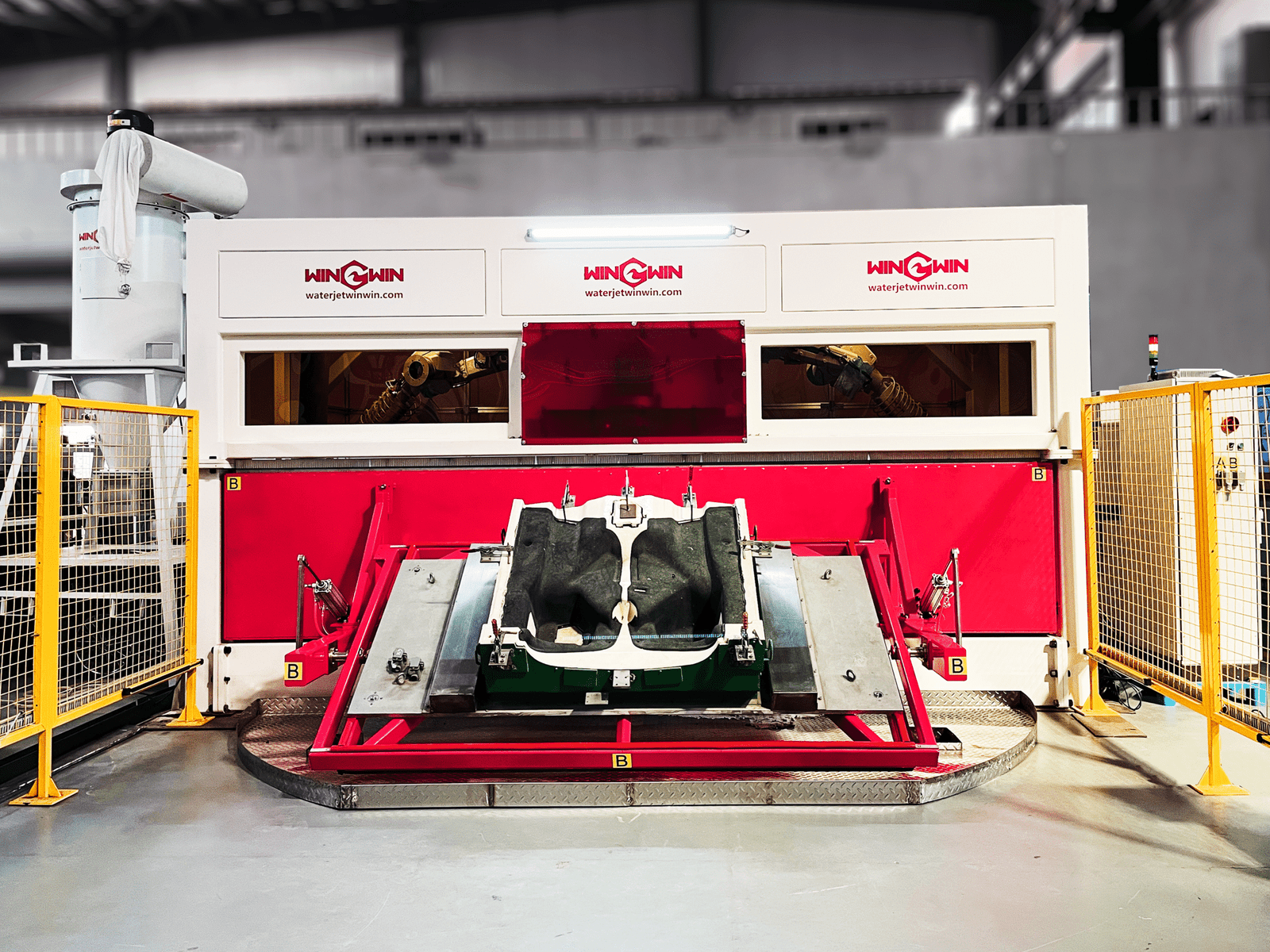

Win-Win’s robotic waterjet cutting technology has been widely applied in BMW’s automotive interior production process, bringing multiple upgrades to the manufacturing link with its advanced performance, and effectively guaranteeing the quality and efficiency of BMW’s interiors.

1.1 High-Precision Cutting, Creating Exquisite Interior Details

BMW’s automotive interiors involve a variety of precision components, and the requirements for size and shape accuracy are extremely strict. Win-Win’s robotic waterjet cutting equipment relies on high-pressure water flow to complete the cutting of materials such as leather, fabric, plastic and composite materials. The cutting precision can reach the micron level, which fully meets the strict specification requirements of BMW’s interior components, and lays a solid foundation for the exquisite texture of BMW’s interiors.

1.2 Strong Material Adaptability, Matching High-End Design Needs

BMW’s high-end models often use a variety of high-end materials such as genuine leather, precious wood veneer and special foam in the interior design to create a luxurious riding experience. Win-Win’s waterjet cutting technology has excellent material adaptability, which can smoothly handle the cutting of the above-mentioned diverse materials without damaging the material properties. This provides greater flexibility for BMW’s interior design, allowing the design team to give full play to their creativity and meet the personalized needs of different models.

1.3 No Heat-Affected Zone, Ensuring Product Integrity

Compared with traditional thermal cutting methods, Win-Win’s waterjet cutting technology does not generate high temperature during the cutting process, so there will be no heat-affected zone on the material. This avoids material deformation, discoloration or internal structure damage caused by high temperature, which is particularly critical for BMW’s high-quality interior production. Even subtle flaws can affect the overall look and feel of the interior, and Win-Win’s technology effectively eliminates this hidden danger.

1.4 Intelligent Automation, Improving Production Efficiency

BMW has a large-scale production demand for automotive interiors, and efficiency improvement is an important goal of its manufacturing link. Win-Win’s robotic waterjet cutting equipment realizes full-process automated production, which can greatly reduce manual intervention, avoid errors caused by manual operation, and at the same time realize 24-hour continuous operation. This not only improves the production efficiency of BMW’s interiors, but also stabilizes the production capacity, ensuring the timely supply of interior components for various models.

1.5 Environmentally Friendly and Low-Waste, Conforming to Sustainable Development Concepts

In recent years, the automotive industry has paid more and more attention to environmental protection and sustainable development, and BMW is no exception. Win-Win’s waterjet cutting technology is a green and environmentally friendly processing method. During the cutting process, it only uses water and abrasive materials, without producing harmful gases or pollutants, and the material waste rate is extremely low. This helps BMW reduce production costs while reducing environmental burdens, and practices the concept of green manufacturing.

2. Win-Win’s Cooperative Layout in BMW’s Interior Supply Chain

BMW’s automotive interior production has a global layout, with production bases distributed in Germany, the United States, China, Eastern Europe and other regions. To ensure the quality and supply stability of interiors, BMW has established long-term cooperative relationships with a number of world-renowned auto parts suppliers, including Faurecia, Continental, Grupo Antolin, Adient, Lear Corporation, Daimler AG and other well-known enterprises.

As a professional waterjet supplier trusted by the industry, Win-Win has established in-depth cooperative relations with three core suppliers of BMW’s interiors, namely Grupo Antolin, Faurecia and Daimler AG. By providing high-performance robotic waterjet cutting equipment and professional technical support, Win-Win helps these suppliers improve their production efficiency and product quality, and indirectly contributes to the high-standard manufacturing of BMW’s automotive interiors. This cooperative relationship not only reflects Win-Win’s strong strength in the field of waterjet technology, but also lays a solid foundation for its in-depth development in the high-end automotive supply chain.

In conclusion, Win-Win’s robotic waterjet cutting equipment has become an important link in BMW’s automotive interior manufacturing system through its excellent performance and environmental protection advantages. The cooperative relationship with BMW’s core suppliers further strengthens the connection between the two parties. If you want to know more about Win-Win’s waterjet equipment applications in the automotive industry or cooperative details, please feel free to contact us.