Description

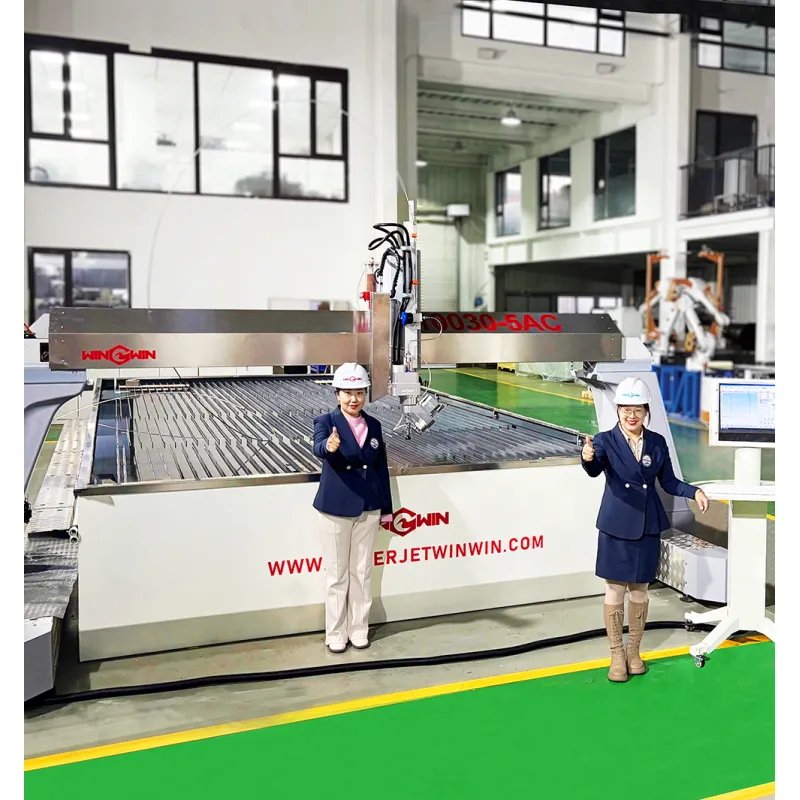

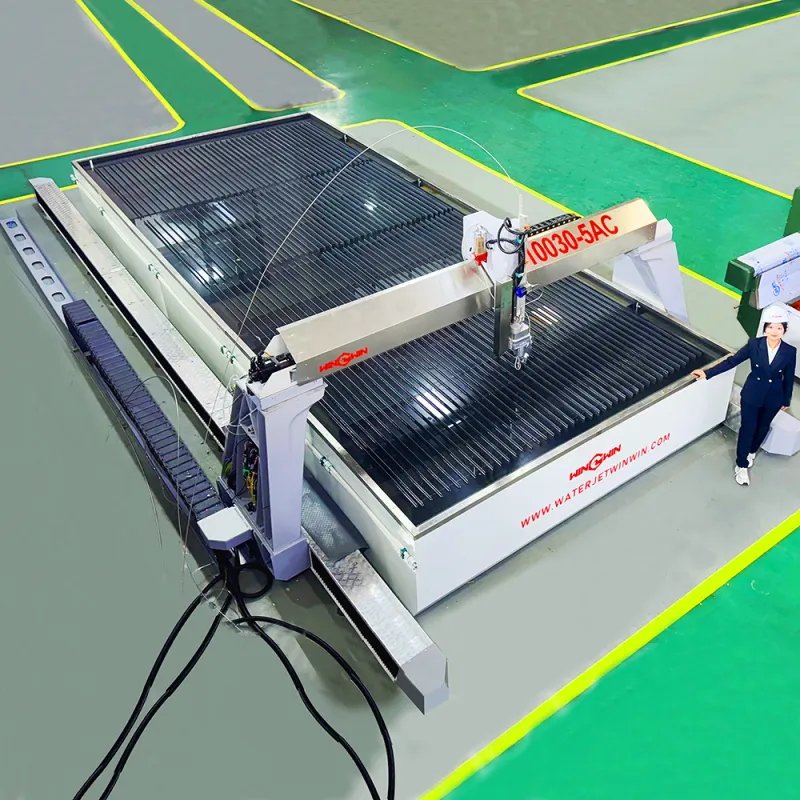

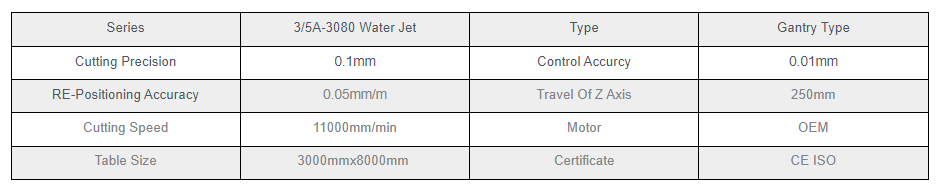

OEM 40*4M WATERJET CUTTING MACHINE

High-stroke Z-axis, bridge-type structure;

Modular Y-axis, LEGO-style docking, maximum length 40 meters;

Modular X-axis, selectable 2m, 2.5m, 3m, 3.5m, 4m;

Multiple X-axis, Z-axis (optional);

Preferred choice for UAV wings and wind turbine blades.

Our product range encompasses a variety of sizes, accommodating projects of all scales, from compact 1*1m machines to expansive 6*3m models, ensuring that every cutting need is met with precision and efficiency. Trust Win Win Waterjet for cutting-edge technology, unparalleled service, and a legacy of excellence that sets us apart in the realm of waterjet cutting machinery.

Floor-standing flipping platform saves time and facilitates loading and unloading.

Thick linear guides and large screw balls. The X, Y axis adopts the self-made oil-immersed screw guide rail lubrication method, which is better than the traditional timing lubrication effect, better dust-proof effect, and service life Longer.

Introduction of Waterjet Machine:

A waterjet cutting machine is a tool that uses a high-pressure stream of water to cut through materials. This technology is known for its precision and versatility in cutting various materials, ranging from soft textiles to hard metals.

Waterjet Cutting Machine Technology:

Waterjet cutting technology involves using a high-pressure pump to force water through a small nozzle at extremely high speeds. In some cases, an abrasive material such as garnet is added to the water to increase the cutting power. The focused stream of water can cut through materials by eroding them with its high velocity.

Materials that can be cut by Waterjet Machine:

Waterjet machines can cut a wide range of materials, including metals like steel, aluminum, and titanium, as well as stone, glass, ceramics, composites, plastics, rubber, and even food products like cakes and vegetables.

Components of Waterjet Cutting System:

Key components of a waterjet cutting system include:

High-pressure pump

Nozzle

Mixing tube

Abrasive feeder (if using abrasive)

Cutting table

CNC controller

Cooling system

Core Technology of Waterjet Cutting Machine:

The core technology of a waterjet cutting machine lies in the high-pressure pump that generates the pressurized water stream. This pump is crucial for creating the high-speed jet that can effectively cut through materials. Additionally, the precision of the cutting is controlled by the CNC system that directs the movement of the cutting head.

Components of Waterjet Cutting System:

Key components of a waterjet cutting system include:

High-pressure pump

Nozzle

Mixing tube

Abrasive feeder (if using abrasive)

Cutting table

CNC controller

Cooling system

Core Technology of Waterjet Cutting Machine:

The core technology of a waterjet cutting machine lies in the high-pressure pump that generates the pressurized water stream. This pump is crucial for creating the high-speed jet that can effectively cut through materials. Additionally, the precision of the cutting is controlled by the CNC system that directs the movement of the cutting head.

Waterjet Equipment FAQ

What is a waterjet cutting machine?

A waterjet cutting machine is a tool that uses a high-pressure stream of water to cut through materials. It can be used for cutting a wide range of materials, including metal, glass, stone, and composites.

How does a waterjet cutting machine work?

Waterjet cutting machines work by pressurizing water and forcing it through a small nozzle at high speeds. Abrasive particles can also be added to the water to enhance cutting capabilities.

What materials can be cut using a waterjet cutting machine?

Waterjet cutting machines can cut through materials such as metal, glass, ceramic, stone, rubber, composites, and more. They are versatile tools suitable for various industries.

What are the advantages of using a waterjet cutting machine?

Advantages of waterjet cutting include high precision, minimal material waste, no heat-affected zones, ability to cut intricate shapes, and environmentally friendly operation.

What is the difference between pure waterjet cutting and abrasive waterjet cutting?

Pure waterjet cutting uses only water for cutting softer materials, while abrasive waterjet cutting involves adding abrasive particles to the water stream for cutting harder materials like metal and stone.

What factors should be considered when choosing a waterjet cutting machine?

Factors to consider include cutting speed, cutting accuracy, material type and thickness, machine size, operating costs, maintenance requirements, and specific application needs.

What maintenance is required for a waterjet cutting machine?

Regular maintenance tasks include checking and replacing abrasive materials, monitoring water quality, inspecting seals and nozzles, and following manufacturer guidelines for upkeep.

Can a waterjet cutting machine be used for 3D cutting?

Yes, waterjet cutting machines can be used for 3D cutting to create complex shapes and contours in materials, making them suitable for various industries like aerospace and automotive.

What safety precautions should be taken when operating a waterjet cutting machine?

Safety precautions include wearing appropriate personal protective equipment, following machine-specific safety guidelines, ensuring proper training for operators, and maintaining a safe work environment.

What industries commonly use waterjet cutting machines?

Industries such as aerospace, automotive, manufacturing, engineering, architecture, metal fabrication, and stone cutting frequently utilize waterjet cutting machines for their precision cutting capabilities and versatility.