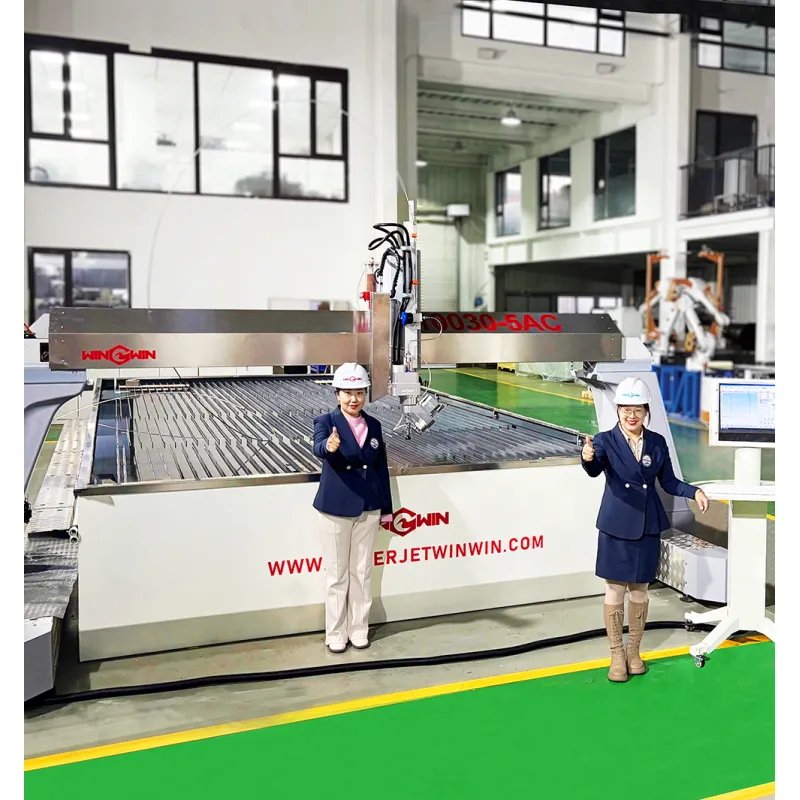

In the realm of large-format precision cutting, manufacturers of aerospace components, wind energy equipment, and heavy industrial parts have long been constrained by the limitations of fixed-size cutting beds, unstable high-speed operation, and inflexible production scalability. For 25 years, Win-Win Waterjet has been at the forefront of waterjet technology innovation, dedicated to solving these pain points for global clients. Today, we proudly unveil our game-changing giant-platform waterjet cutting system—boasting a maximum 40×4m cutting range—to break through the bottlenecks of large-scale component processing.

This ultra-large waterjet cutting system is not a simple upgrade of conventional models, but a tailor-made solution engineered for the most demanding industrial cutting tasks. Every design detail is crafted to balance uncompromising precision, extraordinary stability, and unmatched flexibility, setting a new benchmark for large-format cutting equipment.

Unrivaled Structural Stability for Consistent High-Precision Cuts

The foundation of precise cutting lies in structural rigidity, and this system excels with its heavy-duty bridge-type frame. Even when operating at full speed across the 40m maximum span, the frame effectively eliminates vibration and deflection, ensuring that every cut maintains consistent accuracy from one end of the bed to the other.

Complementing the robust structure is a high-stroke Z-axis, a key upgrade for 3D complex component processing. Whether dealing with the curved surfaces of UAV wings or the layered composite structures of wind turbine blade segments, the extended vertical travel of the Z-axis maintains the optimal standoff distance between the cutting head and the workpiece surface. This guarantees flawless cutting quality, free from delamination or edge defects, even for parts with extreme topographies.

Modular Design: Build a Cutting System That Grows With Your Business

Gone are the days of being locked into a fixed cutting bed size that fails to meet evolving production needs. Our system features a revolutionary modular design that brings unprecedented flexibility to large-format cutting.

The LEGO-style modular Y-axis allows for on-demand extension, with a maximum length of 40 meters. You can start with a configuration that fits your current projects and expand the length quickly and easily as your business scales—no need to invest in a brand-new machine when your part sizes grow. This future-proof design protects your capital investment and adapts to changing market demands.

On the X-axis, we offer configurable width options ranging from 2m to 4m. This lets you select the exact width that matches your factory floor layout and production requirements, avoiding wasted space and unnecessary costs. It’s a customized cutting solution that integrates seamlessly into your existing manufacturing ecosystem.

Multi-Axis Configuration: Supercharge Your Production Throughput

For high-volume manufacturing facilities, productivity is the key to profitability. Our giant-platform waterjet addresses this need with an optional multi-X and multi-Z axis configuration. Equipping a single gantry with multiple independent cutting heads transforms the machine into a high-throughput production line.

Imagine cutting multiple identical large components simultaneously, or assigning one head for rough cutting and another for precision finishing in a single pass. This parallel processing capability drastically reduces cycle times, slashes production lead times, and maximizes your return on investment—turning a single large-format cutter into a multi-tasking production powerhouse.

The Go-To Solution for Aerospace and Renewable Energy Industries

The combination of all these cutting-edge features makes this system the ideal choice for two of the fastest-growing and most precision-critical industries: aerospace and renewable energy.

In UAV wing manufacturing, the system’s high-stroke Z-axis effortlessly follows the aerodynamic curves of carbon fiber composites, delivering precise trimming and hole-drilling without causing material delamination. The zero heat-affected zone of waterjet cutting preserves the structural integrity of these high-performance components.

For wind turbine blade production, the 40m maximum length easily accommodates massive blade segments and root-end rings. The ability to perform trimming, edge profiling, and hole machining in a single setup eliminates the need for multiple handling and repositioning steps, streamlining the production process and ensuring the structural reliability of these energy-critical parts.

25 Years of Expertise: Your Reliable Partner for Large-Format Cutting

A high-performance machine is only as good as the support behind it. With 25 years of experience in waterjet technology, Win-Win Waterjet doesn’t just sell equipment—we build long-term partnerships. Our global network of service engineers and application specialists is on hand to provide on-site installation, commissioning, training, and maintenance support, ensuring maximum uptime for your production line, no matter where you are in the world.

This giant-platform waterjet cutting system is more than a piece of machinery; it’s a strategic investment that empowers you to take on bigger projects, meet tighter deadlines, and stay ahead of the competition. It’s a testament to our 25-year legacy of innovation and our commitment to driving the future of large-format precision cutting.

Step into the new era of large-scale waterjet cutting—contact Win-Win Waterjet today to learn more about our 40×4m giant-platform system and customize your perfect cutting solution.